|

Application Used of motorized spindle , DC motor , Servo motor

Motor encoders are used in many applicaions that reauire precise shat unlimited rotaion-incuding industrial controls. robotics. speciapurpose photographic lenses,computer input devices (such as optomechanical mice and trackballs), controlled stress rheometers, and

rotating radar platforms.

Features Miniature size , low cost Access data by a special matrix, high correction ability ,reliability and long life Different material for optional: Film, stainless steel, glass

A motor encoder, is an electro-mechanical device that converis the angular position or motion of a shaf or axleto an analog or digital code.

There are two main types: absolute and incremental (relative). The output of absolute encoders indicates the curent position of the shaftmaking them angle transducers. The output of incremental encoders provides information about the motion of the shaf, which is typicallyfurther processed elsewhere into information such as speed, distance and position.

|

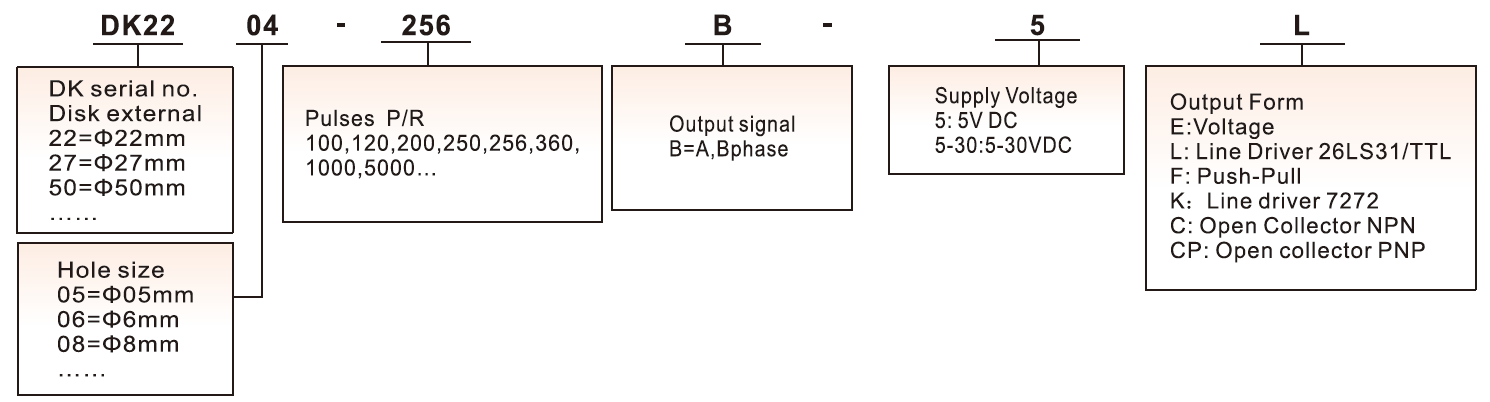

Ordering Information

Note

1, Please contact sales representative to confirm the correctness and availability of the part number

2. If with grating base max hole size 10mm, without grating base max hole size 17mm

Technical Specifications

|

Specification |

Code |

Metal grating |

Film grating |

Glass grating |

|

Storage temperature |

Ts |

-40~100℃ |

-40~85℃ |

-40~100℃ |

|

Working temperature |

TA |

-40~100℃ |

-40~85℃ |

-40~100℃ |

|

Speed |

- |

30,000RPM |

30,000PRM |

12,000RPM |

|

Humidity |

- |

- |

Non condensing |

- |

|

- |

250,000Rad/Sec2 |

250,000Rad/Sec2 |

100,000Rad/Sec2 |

|

|

Disk thickness |

T |

≥0.05mm |

0.178mm |

≥0.6mm |

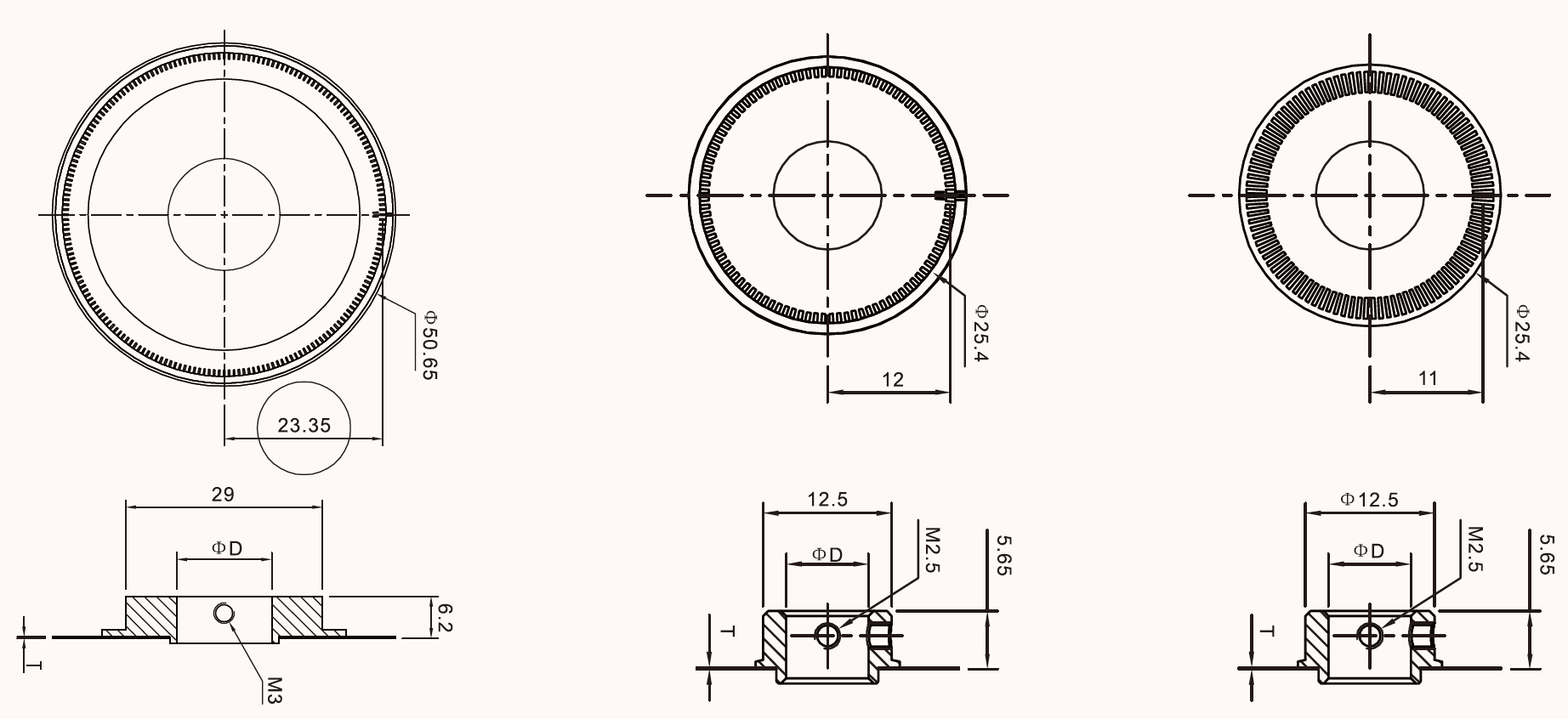

Dimensions(mm)