Use and characteristics

High torque rigidity and high sensitivity.

Zero rotation gap.

Clockwise and counterclockwise rotation characteristics are exactly the same.

Stainless steel diaphragm compensates for angular and axial deviations.

Applications

1. Widely used in various mechanical and hydraulic fields

2. Small dimension, low weight, high transmitted torque

3. Elastomers made of polyurethane with shore hardness between 80-98

4. Compensating the axial relative drift, buffer and vibration reduction

5. Material: cast iron, steel and aluminum alloy

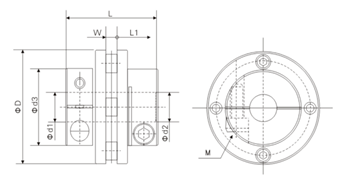

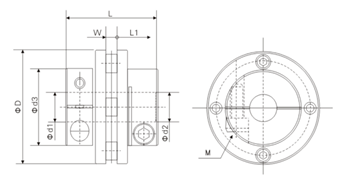

Dimensions

|

Model

|

D

|

L

|

d1 d2 shaft dia.

|

L3

|

M

|

L1

|

Tightening torque(N.m)

|

|

LE-34 27/XX/XX

|

34

|

27

|

6-10

|

2-m3*10

|

12

|

3.2

|

1.5

|

|

LE-40 34/XX/XX

|

40

|

34

|

8-12

|

2-m4*12

|

15

|

4.3

|

2.5

|

|

LE-44 34/XX/XX

|

44

|

34

|

8-16

|

2-m4*12

|

15

|

4.3

|

2.5

|

|

LE-56 45/XX/XX

|

56

|

45

|

10-24

|

2-m5*16

|

20

|

5.2

|

7

|

|

LE-68 54/XX/XX

|

68

|

54

|

10-25

|

2-m6*25

|

24

|

6

|

12

|

|

LE-82 68/XX/XX

|

82

|

68

|

10-30

|

2-m8*30

|

30

|

8

|

20

|

Product features

|

Model

|

Rated torque

(N.m)

|

Maximum torque

(N.m)

|

Maximum speed

(rpm)

|

Inertia moment

(kg.m²)

|

Static torque rigidity

(N.m/rad)

|

Radial deviation (mm)

|

Angle deviation

(ºC)

|

Axial deviation

(mm)

|

Weight

(g)

|

|

LE-34 27/XX/XX

|

2

|

4

|

10000

|

3.8*10-6

|

3300

|

0.1

|

1

|

±0.15

|

30

|

|

LE-40 34/XX/XX

|

4.5

|

9

|

10000

|

1.1*10-5

|

7000

|

0.1

|

1

|

±0.23

|

52

|

|

LE-44 34/XX/XX

|

6.75

|

13.5

|

10000

|

1.6*10-5

|

9000

|

0.1

|

1

|

±0.27

|

70

|

|

LE-56 45/XX/XX

|

20

|

40

|

10000

|

5.1*10-5

|

20000

|

0.1

|

1

|

±0.36

|

165

|

|

LE-68 54/XX/XX

|

50

|

100

|

9000

|

1.3*10-4

|

35000

|

0.1

|

1

|

±0.4

|

275

|

|

LE-82 68/XX/XX

|

80

|

160

|

8000

|

1.9*10-4

|

54000

|

0.1

|

1

|

±0.5

|

450

|

.jpg)