YUMO IHC3808 Encoder hollow shaft rotary encoder high resolution rotary encoder 38mm IP51

Application

Automatic control, measurements, robotic X-Y labor and printing machines.

Features

High reliability, long life, strong anti-interference ability and wide range of temperature adaption.

A Hollow-Shaft Incremental Rotary Encoder, also called a hollow shaft encoder, is an electro-mechanical device that converis the angular position or motion of a shaf or axleto an analog or digital code.

There are two main types: absolute and incremental (relative). The output of absolute encoders indicates the curent position of the shaftmaking them angle transducers. The output of incremental encoders provides information about the motion of the shaf, which is typicallyfurther processed elsewhere into information such as speed, distance and position.

Ordering Information

Technical Specifications

|

Electrical Specification |

||||

|

Output circuit |

Open collector |

Voltage output |

Push pull output |

Line driver output |

|

Power Vcc |

5~30 |

5~30 |

5±0.25 5~30 |

5±0.25 5~30 |

|

Current |

≤80mA |

≤80mA |

≤80mA |

≤150mA |

|

Load current |

40mA |

40mA |

40mA |

60mA |

|

High-level output |

Min Vcc*70% |

Min Vcc-2.5V |

Min Vcc-1.5V |

Min 3.4V |

|

Low-level output |

Max 0.4V |

Max 0.4V |

Max 0.8V |

Max 0.4V |

|

Rise Time Tr |

Max 1us |

Max 1us |

Max 1us |

Max 200ns |

|

Fall Time Tr |

Max 1us |

Max 1us |

Max 1us |

Max 200ns |

|

Max Responding Frequency |

300kHz |

300kHz |

300kHz |

300kHz |

|

Mechanical Specification |

||||

|

Max speed(r/min) |

Starting Torque |

Max. Shaft Loading |

Shocking |

Vibration |

|

6000 |

<0.05Nm |

Radial:50N, Axial:20N |

50G/11-ms |

10G 10-2000Hz |

|

Rotor Inertia |

Working Temperature |

Storage Temperature |

Protection Grade |

Weight |

|

4*10-8Kgm2 |

-30~85℃ |

-35~95℃ |

IP51 |

100g |

Connection Table

|

Signal |

A |

B |

Z |

A(-) |

B(-) |

Z(-) |

Vcc |

GND |

|

Color |

Green |

White |

Yellow |

Brown |

Gray |

Orange |

Red |

Black |

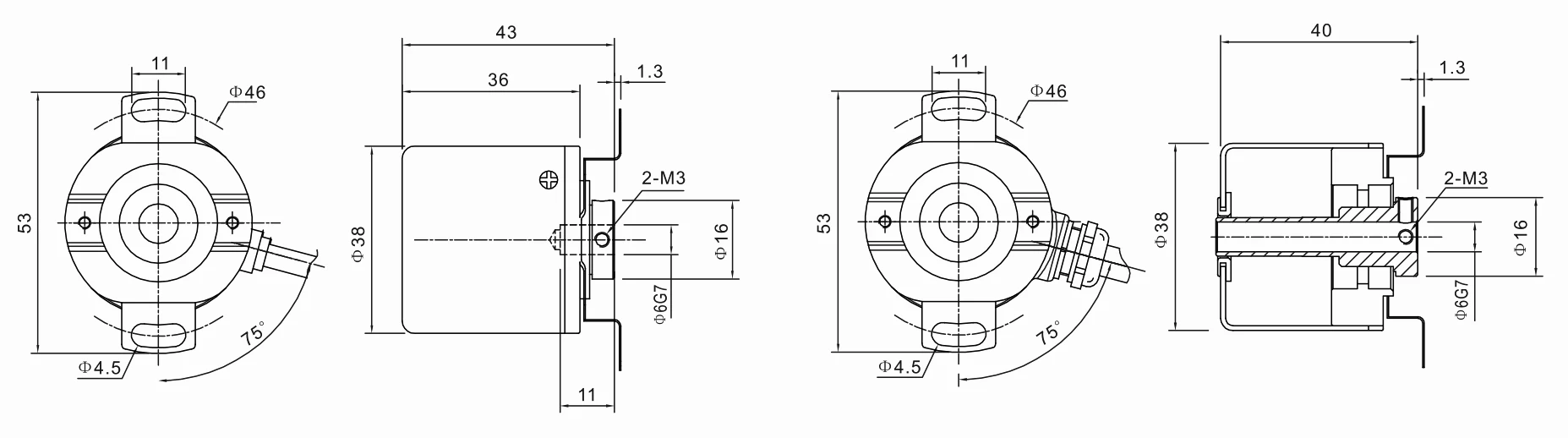

Dimensions(mm)