Feature:

A Solid Shaft Absolute Rotary Encoder, also called a absolute encoder, is an electro-mechanical device that converis the angular position or motion of a shaf or axleto an analog or digital code.

There are two main types: absolute and incremental (relative). The output of absolute encoders indicates the curent position of the shaft making them angle transducers. The output of incremental encoders provides information about the motion of the shaf, which is typically further processed elsewhere into information such as speed, distance and position.

Application:

Absolute encoders are used in many applicaions that reauire precise shat unlimited rotaion-incuding industrial controls. robotics. Specia purpose photographic lenses,computer input devices (such as optomechanical mice and trackballs), controlled stress rheometers, and rotating radar platforms.

|

|

Absolute |

Incremental

ERN 487 |

|

|

ECN 425 |

ECN 413 |

||

|

Part number |

683644-xx |

1065932-xx |

749143-xx |

|

Interface1) |

EnDat 2.2 |

1 VPP |

|

|

Ordering designation |

EnDat22 |

EnDat01 |

– |

|

Position values/revolution |

33554432 (25 bits) |

8192 (13 bits) |

Z1 track3) |

|

Electrically permissible speed/error2) |

12000 rpm (for continuous position value) |

1500 rpm/±1 LSB 12000 rpm/±50 LSB |

– |

|

Calculation time tcal Clock frequency |

7 µs 8 MHz |

9 µs 2 MHz |

– |

|

Incremental signals1) |

– |

1 VPP |

1 VPP |

|

Line count/system accuracy |

2048/±20“ |

||

|

Reference mark |

– |

One |

|

|

Cutoff frequency –3 dB |

– |

400 kHz |

210 kHz |

|

Electrical connection* |

Cable 1 m/5 m with M12 coupling |

Cable 1 m/5 m without coupling |

Cable 1 m/5 m without coupling |

|

Voltage supply |

DC 3.6 V to 14 V |

DC 5 V ±0.25 V |

|

|

Power consumption1) (maximum) |

3.6 V: 600 mW 14 V: 700 mW |

– |

|

|

Current consumption |

5 V: 85 mA (typical, without load) |

130 mA (without load) |

|

|

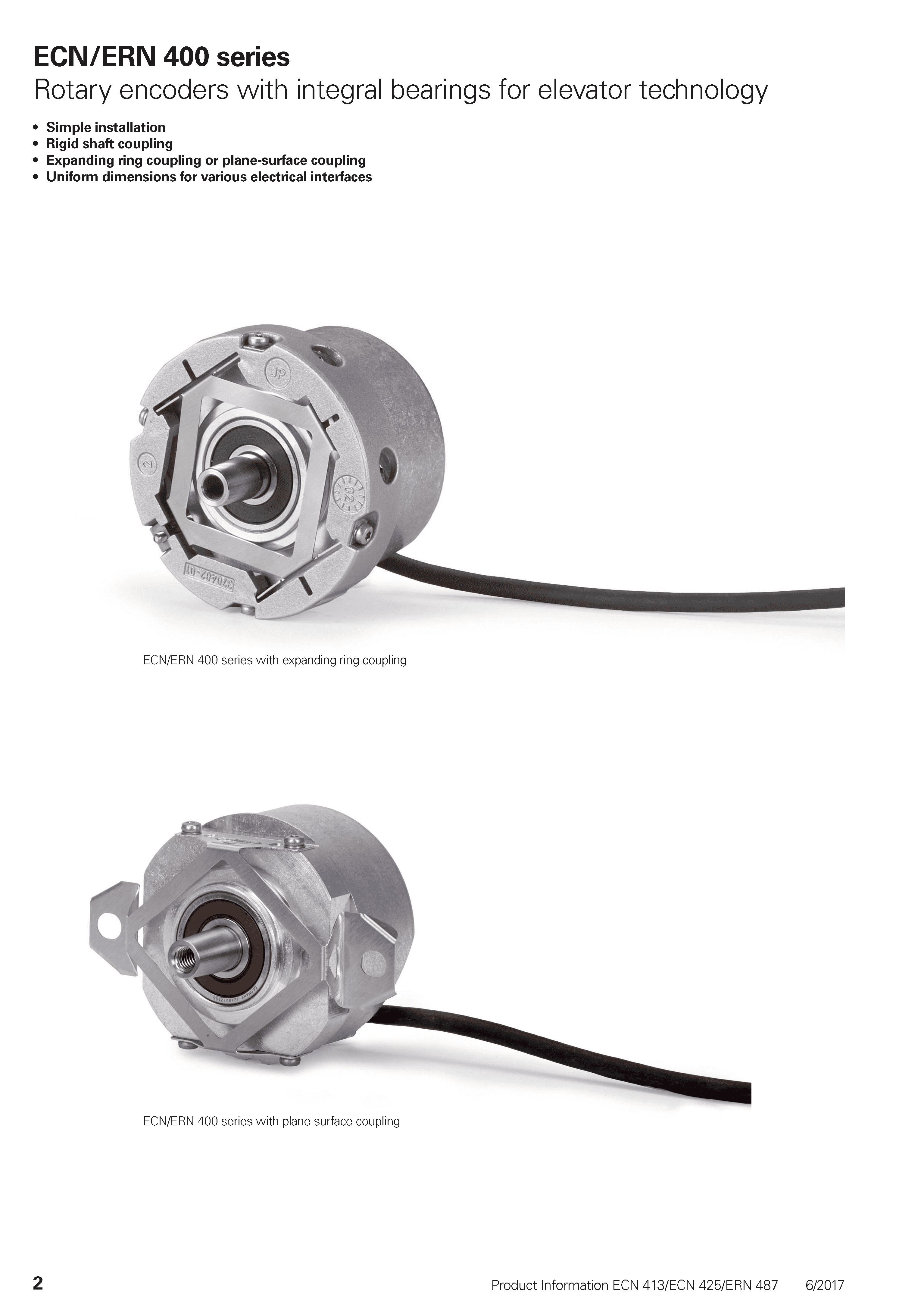

Stator coupling* |

Expanding ring coupling or plane-surface coupling |

||

|

Shaft |

Taper shaft 9.25 mm; taper 1:10 |

||

|

Mech. permiss. speed n |

Expanding ring coupling: 12000 rpm Plane-surface coupling: 2000 rpm |

||

|

Starting torque |

0.01 Nm (at 20 °C) |

||

|

Moment of inertia of rotor |

2.6 · 10–6 kgm2 |

||

|

Permissible axial motion of the measured shaft4) |

Expanding ring coupling: ±0.5 mm Plane-surface coupling: ±1.5 mm |

||

|

Radial runout of the measured shaft |

Expanding ring coupling: 0.02 mm Plane-surface coupling: 0.13 mm (for static radial mounting tolerance also ±0.13 mm) |

||

|

Vibration 55 Hz to 2000 Hz Shock 6 ms |

300 m/s2 (EN 60 068-2-6) 2000 m/s2 (EN 60 068-2-27) |

||

|

Operating temperature |

–10 °C to +100 °C |

||

|

Protection EN 60529 |

IP 64 |

||

|

Mass |

» 0.25 kg |

||