Prior to the invention of the PLC, automation relied heavily on relays, a type of electrical switch that uses a coil to create a magnetic force and control the on/off state of devices like motors or lights. To control multiple devices in a factory or manufacturing plant, engineers would wire a network of relays together, forming complex control circuits. While this worked in theory, the system presented numerous problems.

In a typical factory, controlling even a single motor might require several relays: power relays to switch the motor on or off, and control relays to manage the power relays. As factories expanded, these systems became more complicated, with electrical cabinets packed full of relays and wires. The control systems quickly became difficult to manage. With so many interconnected components, any failure in one relay could cause the entire system to fail, making troubleshooting a major challenge. Maintenance became increasingly difficult as the systems grew in size, and any change to the system required extensive rewiring, which led to inefficiencies and delays.

An engineer from the early 1970s recalls the difficulties of working with relay-based systems: “I began working as a controls designer, automating machinery with industrial relays, pneumatic timers, and electro-mechanical counters. The control systems I designed often had over 100 relays and were housed in large electrical enclosures. As time went on, the wiring became more tangled, making the systems unreliable and increasingly difficult to troubleshoot.”

The solution to the problems of relay-based control came from the Hydra-Matic division of General Motors (GM), where engineers were seeking a more efficient way to automate machinery. In 1968, these engineers, along with a small company called Bedford Associates, began to explore the possibility of using computer control in industrial environments. The result was the first programmable controller, which was officially conceptualized on New Year’s Day, 1968, by Dick Morley, who is now regarded as the father of the PLC.

GM’s requirements for the new controller were clear: it had to be a solid-state system, capable of replacing the relays while being flexible and competitively priced. The system needed to be easy to program and maintain, working in the harsh industrial environment of factories, and it had to be modular, allowing for easy upgrades and expansions. Most importantly, the new controller had to be programmable using a method that was familiar to those who had worked with relays: ladder logic. This form of programming mirrored the physical layout of relays, making it easier for electricians and maintenance personnel to transition from the old system to the new.

The initial PLC prototypes were far from perfect. The very first machine designed for GM, which had only 125 words of memory, quickly ran into problems. As Dick Morley recalls, the machine was too slow and lacked the memory capacity to handle the complexities of the relay-based control systems it was meant to replace. Engineers soon upgraded the memory to 1K, and later to 4K, which allowed the system to handle more complex operations.

Despite these early setbacks, the idea behind the PLC was groundbreaking, and engineers quickly recognized its potential. However, even the first generation of PLCs was not without challenges. A control designer who worked with one of the early PLC models recalls his experience: "The first PLC I worked with was programmed with a suitcase-sized device. The programming was clunky, and the physical design of the PLC left the components exposed to potential electrical shorts, which could disable the entire system."

The turning point came when Dick Morley and his company, Modicon, began selling their first PLC, the Modicon 084. Though it struggled to gain traction in the marketplace initially, the Modicon 084 represented a significant leap forward in industrial automation. It replaced complex relay systems with a more efficient, programmable controller. It was the Modicon 084 that GM ultimately adopted to automate its manufacturing systems.

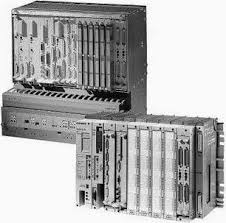

However, it was the development of the Modicon 184 that truly revolutionized the PLC industry. Designed by Michael Greenberg and Lee Rousseau, the Modicon 184 was built with customer needs in mind, featuring expanded capabilities and greater reliability. It included timers, counters, analog inputs and outputs, and PID control functions, making it ideal for process control applications. The success of the Modicon 184 marked the beginning of PLCs becoming a mainstream solution for automation in industries around the world.

As PLCs continued to evolve, they became increasingly sophisticated. Early models offered basic functionality, such as input and output control, relay logic, and simple timers. Over time, PLCs gained the ability to handle more complex tasks, including analog signals, floating-point math, and advanced mathematical functions. Ladder logic programming evolved, making PLCs easier to program and adapt to different automation tasks.

The introduction of communication protocols such as MODBUS allowed PLCs to communicate with other industrial devices like HMIs, motor drives, and remote sensors. As communications technology advanced, PLCs became more networked, facilitating greater integration with other control systems.

The rise of Ethernet-based communication protocols, such as Ethernet/IP, further expanded the capabilities of PLCs. These advances enabled greater interoperability and faster data transmission, leading to improved control and monitoring across large, distributed networks of industrial systems.

Today, PLCs are found in nearly every sector of industry, from automated manufacturing to energy management and building automation. The technology has become an essential part of modern control systems, allowing businesses to improve efficiency, reduce downtime, and enhance safety.

From the early days of relay-based control systems to the advanced, networked PLCs of today, the history of the PLC is one of continuous improvement. What began as a solution to the logistical nightmare of relay systems has evolved into a powerful and flexible tool that continues to shape the future of industrial automation.

As the Internet of Things (IoT) and cloud computing further integrate with automation technologies, the PLC will likely continue to evolve, pushing the boundaries of industrial control and monitoring. Its history is not just a tale of technological progress, but a reflection of the changing demands of industry, and the ongoing drive for greater efficiency, reliability, and flexibility in automation systems.

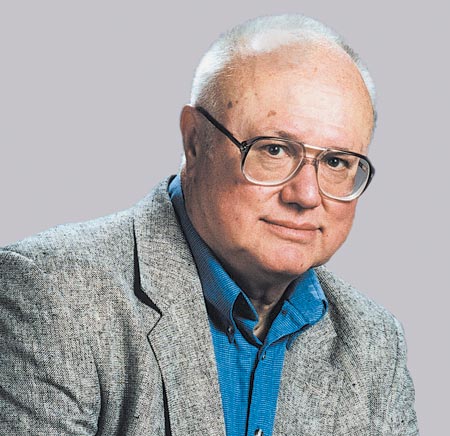

The history of the Programmable Logic Controller (PLC) is intrinsically tied to the vision and ingenuity of one man: Dick Morley, widely recognized as the father of the PLC. Morley’s journey from an uncertain, unemployed engineer to the creator of one of the most important innovations in industrial automation is a remarkable tale of determination, creativity, and a bit of serendipity.

Born with a natural curiosity and a keen interest in engineering, Dick Morley was far from the typical inventor. Before his groundbreaking work in industrial automation, Morley had a diverse and rather unconventional career. By 1964, he found himself unemployed, with a new baby, a mortgage, and just $1,000 in the bank. Prior to this, Morley had worked on high-profile defense projects, including designing atomic bombs, airplanes, and communication systems. However, despite his technical accomplishments, Morley was dissatisfied with his desk job, feeling confined by the rigid structure of his assignments.

It was during this period of uncertainty that Morley’s passion for skiing led him to re-evaluate his life choices. Quitting his job, he turned to consulting, eventually starting his own firm called Bedford Associates with his friend George Schwenk in Bedford, Massachusetts. The firm worked with local machine tool manufacturers, helping them transition to solid-state technologies. Though the work was lucrative, Morley quickly grew bored. He noticed that his projects were beginning to follow a predictable, repetitive pattern, all involving similar minicomputers. The thrill of new challenges seemed to be slipping away.

It was during this phase of frustration and creative stagnation that Morley’s revolutionary idea for the PLC began to take shape. Inspired by the limitations of existing relay-based control systems, Morley began wondering if he could create a programmable controller that could automate industrial processes with multiple input/output arrangements in real-time. The idea was simple but profound: replace the massive, hardwired relay systems used on factory floors with a flexible, solid-state system that could be easily programmed to control machinery.

Before the invention of the PLC, industrial control systems relied on massive relay rooms—essentially, large control panels filled with thousands of relays, wires, and terminal blocks. These systems were highly inflexible, prone to failure, and extremely difficult to troubleshoot. Maintenance workers often had to spend hours or even days identifying problems in these complex, tangled wiring systems. The phrase “Five hours to find it, five minutes to fix it” became a commonly heard lament.

Morley believed there had to be a better way. He envisioned a device that could automate tasks, streamline operations, and save time. This vision was the beginning of the Programmable Logic Controller.

Morley’s breakthrough moment came on New Year’s Day, 1968. After spending a festive night nursing a hangover, Morley sat down with pen and paper to outline the concept for his programmable controller. By the end of the day, he had mapped out the essential functions of what would later become the PLC—a compact, flexible, and programmable control unit that could be used to replace relay systems in manufacturing environments.

Morley wasn’t working alone, though. He enlisted the help of talented engineers Mike Greenberg, Jonas Landau, and Tom Boissevain. Together, they designed the first PLC, which they called Project 084—named after the 84th project that Bedford Associates had undertaken. This early prototype was designed to be robust, capable of withstanding harsh factory conditions such as extreme temperatures, humidity, and dirt. Unlike the traditional relay control systems, which required sealed cabinets to protect their components, the PLC’s design included metal fins that allowed for natural cooling without letting dirty air into the electronics.

In October of 1968, after securing financial backing, Morley and his team founded Modicon, the company that would go on to commercialize the first PLC. At the time, General Motors’ Hydra-Matic Division was also searching for a solution to automate its production lines. GM needed a single controller capable of managing a variety of tasks on a production assembly line. Morley’s PLC met that need perfectly, and the idea quickly gained traction.

With the creation of the Modicon 084 in 1968, the PLC began its journey from concept to reality. The introduction of the PLC fundamentally altered the world of industrial automation. Instead of relying on complicated, hardwired relay systems, engineers and maintenance workers now had access to a programmable device that could be easily adapted to different tasks. The PLC allowed for flexible, modular control systems that could be reprogrammed without the need for extensive rewiring, providing a level of ease and efficiency previously thought impossible.

The PLC’s ability to manage complex processes with multiple inputs and outputs in real-time quickly made it an essential tool in factories, chemical plants, food processing industries, and even environmental systems. For the first time, a control system could not only switch devices on and off but also change variables such as voltage, speed, and timing—features that were beyond the capability of traditional relay systems.

Over 50 years later, the PLC remains a cornerstone of industrial automation. Morley’s vision has grown into a global industry, with companies like Schneider Electric, Siemens, Fanuc, and Omron now manufacturing PLCs that control everything from assembly lines to robotics and energy management systems. Morley’s revolutionary invention gave rise to a new era of flexible automation, where control systems could be easily adjusted, monitored, and integrated with other technologies.

Beyond his technical achievements, Dick Morley’s story is also a testament to the power of creativity and persistence. He didn’t set out to change the world of industrial automation; he simply wanted to solve a practical problem. But in doing so, he forever altered the way that manufacturing processes are controlled and monitored.

Today, the PLC continues to evolve alongside emerging technologies such as Internet of Things (IoT) devices and cloud computing. But despite all the advancements in automation, the principles Morley laid out in the 1960s still govern the design and function of PLCs.

As we look back on the remarkable history of the PLC, it’s clear that Dick Morley’s legacy as the father of industrial automation is secure. His innovation has not only reshaped industries but also paved the way for the modern world of automated production that we rely on every day.